Quick Takeaway:

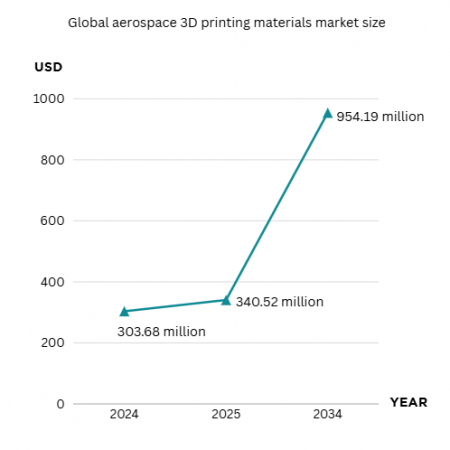

- How is the 3D printing market performing in the aerospace industry? 3D-printed materials are sought after due to their high demand and solutions to logistical challenges. The market is expected to grow from USD 340.52 million to USD 954.19 million by 2034.

- What are the benefits of using robotics in aircraft maintenance? It saves time and maintenance costs and provides greater precision checks and safety measures.

- Will robots and 3D printers replace aircraft maintenance professionals? No, their roles elevate as they oversee these automated systems to ensure their functionality and interpret collected data.

Advancements in the Maintenance, Repair and Overhaul (MRO) sector are actively reshaping the aviation industry, creating a wave of emerging MRO careers for aviation professionals who intend to leverage this opportunity and be part of this evolution. Its profound innovation can be seen in using leading technology like artificial intelligence, blockchain, data analysis, predictive maintenance techniques, and the next big thing, robotics and three-dimensional (3D) printing.

These are just a few examples of hundreds of other initiatives actively used in aircraft maintenance.

The Robotics Revolution in Aircraft Maintenance

A Global Fleet and MRO Market Forecast report states that commercial airliners will continuously expand from a current fleet of 29,000 to 38,300 by the start of 2035 , which is a 32% increase and a compound annual growth (CAGR) rate of 2.8%.

This data shows rapid growth, and more aircraft maintenance professionals are expected. Servicing modern aircraft becomes increasingly complex and requires high-precision skills. That is where Aviation Robotics make its most significant impact as a powerful tool in the MRO sector.

Robots and drones will reduce the five to six hours required for an average visual inspection of a commercial aircraft, saving time and cost and offering greater accuracy and safety.

Examples of companies that are developing and using robotics in aircraft maintenance are:

- Rolls-Royce, which created prototypes of 10 mm-wide cockroach-inspired robots deployed in ‘swarms’ to inspect tightly confined spaces and hard-to-reach components

- SR Technics partnered with Invert Robotics to implement revolutionary robotic solutions. Its high-definition cameras and sensor technology enable recording and transmitting video images for real-time analysis and visual inspection for detailed repair assessments.

3D Printing and the Future of the Aviation Supply Chain

3D printing was a game-changer for the persistent logistics challenges in the MRO sector. These challenges include sourcing or importing specific parts, leading to lengthy aircraft-on-ground (AOG) situations that cost airlines millions.

Metal additive manufacturing is critical in aviation supply chain management. It creates intricate designs of aerospace brackets, engine parts and defence system components that cannot be traditionally achieved.

How Technology Adaptations are Creating New Opportunities within the Asia Pacific MRO Landscape

Japan MRO

All Nippon Airways (ANA) has been working on its ‘AVIATAR’ robotics program, which includes developing telepresence robots for remote inspections and maintenance tasks.

JAL Engineering has also pioneered digital transformation (DX) in aircraft maintenance and failure-critical fields, using the guiding “Zero Zero 100” philosophy to identify and prevent aircraft failures before they occur.

Hong Kong MRO

Australia MRO

How do these advancements impact the aviation job market?

Introducing technology into the hangar may raise concerns if jobs are being replaced.

On the contrary, the engine overhaul sector in air transport commands a 41% market share. This points to a clear conclusion: demand for aircraft engineers is high, and complex MRO is now a long-term structural reality.

To meet soaring demands, the APAC region alone will require 119,000 new aircraft maintenance professionals, as 83% of these professionals will retire or leave the profession globally within the next decade.

Manual and repetitive tasks will shift to more oversight, quality control, and complex problem-solving. This will position you from being an aircraft mechanic to a technical expert in advanced systems and technology.

As an aircraft maintenance engineer and technician, your role will significantly elevate as you oversee these automated systems to ensure their functionality and interpret collected data. In other words, your human intelligence will lead the robotic workforce, creating a smooth ecosystem.

This is where working with specialist aviation staffing partners like OAI becomes invaluable. We leverage our deep industry expertise and global networks that connect licensed aircraft engineers and technicians with roles in thriving markets, transforming a career challenge into a worldwide opportunity.

These are some sought-after jobs in the aviation industry:

- 3D Printing Technician

- 3D Printing Engineer

- 3D Modeller and Designer

- Quality Control Inspector

- Software Engineers (Automation and Robotics)

- Continuous Improvement Engineer (Aerospace MRO)